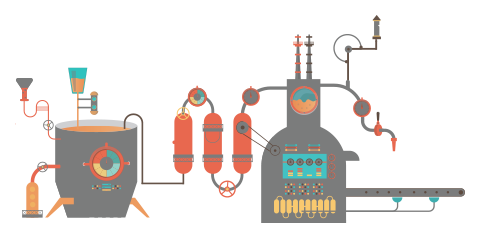

Our pricing is all-inclusive and never includes any additional costs. All three equipment packages include installation and training and are specific for a 5 BBL single batch brewpub brewing system. We also offer the option of a live video stream on the installation crew during installation only to ensure that the job is being recorded, televised, supervised, and done properly by partners or 3rd party purchasers. We can also give the purchaser access to the video feed when they are away from the business to monitor the installation on their phone, tablet, or computer.

When you invest or become a partner in a brewery, the brewing equipment is worth a substantial amount of money and for those looking to buy a business with tangible assets, the equipment retains its value, creates income, and produces pleasure and mitigates and reduces your financial exposure. The manufacturer of the brewery equipment meets UL standards and certification. UL Listing means that UL has tested representative samples of a product and determined that it meets UL’s requirements. These requirements are often based on UL’s published and nationally recognized Standards for Safety.

After deciding to become a partner or invest in a brewery project, you will be given a shareholder’s operational agreement, which stipulates everyone’s responsibilities in the agreement and spells out exact dates, amounts, and responsibilities, and liabilities for all parties. For those looking just to buy the brewery equipment you will be given a purchase and sales agreement to review and sign, you will be asked to provide a deposit equal to 1/2 of the purchase amount reflected on the sales agreement. Just prior to the equipment shipping, you will be required to pay the remaining 1/2 of the balance of the purchase agreement. Depending on the manufacturer, the timelines are approximately 180 days (+/-). Special and customized equipment orders from some manufacturers might take longer. Any representation of projections, forecasts, estimates, or predictions for presentations and proposal purposes are based on historical data from the existing successful, verified, and proven business models created by our managing partners and directors over the last decade.

A brewery that produces less than 15,000 barrels (17,600 hectoliters) of beer per year with 75 percent or more of its beer sold off-site. Microbreweries sell to the public by one or more of the following methods: the traditional three-tier system (brewer to wholesaler to retailer to consumer); the two-tier system (brewer acting as a wholesaler to retailer to consumer); and directly to the consumer through carry-outs and/or on-site taproom or restaurant sales.

A business that hires another brewery to produce its beer. It can also be a brewery that hires another brewery to produce additional beer. The contract brewing company handles marketing, sales, and distribution of its beer, while generally leaving the brewing and packaging to its producer-brewery (which is also sometimes referred to as a contract brewery).

A brewery with an annual beer production of between 15,000 and 6,000,000 barrels.